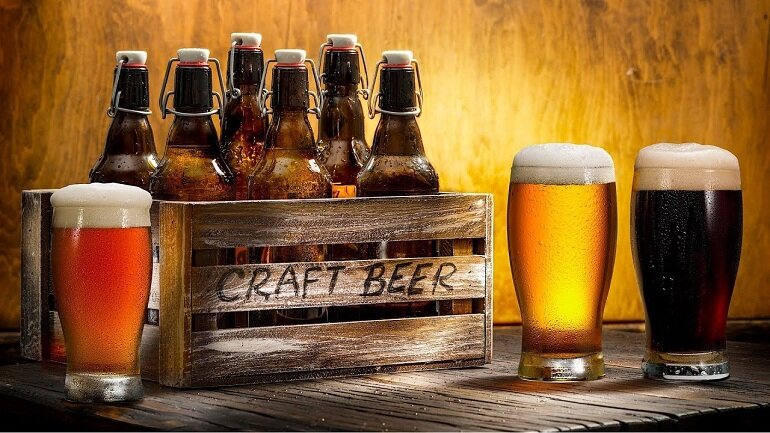

If you are interested in learning and distinguishing between craft beer and mass-produced commercial industrial beer, this article is for you!

First, we need to understand exactly what beer is:

– Beer is the third most popular drink in the world, after water and tea.

– Beer is the number one popular alcoholic beverage.

– The history of beer production is very long, dating back to 9,000 BC.

– According to the law on prevention of harmful effects of alcohol, beer is a food-based alcoholic beverage, produced by fermentation from a mixture of main ingredients including malt, barley, and mushrooms. Brewer’s yeast, hops (hops), water.

1. Similarities between craft beer and industrial beer

Craft beer and industrial beer are both brewed using water, malt, hops and yeast as ingredients. These four famous basic raw ingredients are used to produce the beers we know and love today.

2. Distinguish between craft beer and industrial beer

It can be said that craft beer is art, virtuosity and exclusivity. Craft beer is the result of a whim of a master brewer. That is why in the world of craft beer one can let one’s imagination run wild, something that is not the case with industrial beer, which always aims to produce thousands of liters to maximize income.

AZOUTDOOR Large Towel Warmers for Bathroom, Wifi Remote Control Timed Hot Towel Warmer for Facials, 20L Luxury Capacity Towel Warmers for Spa, Hotel, Salon, Baby Care(Grey)

$109.98 (as of December 22, 2024 00:30 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Salon Tray Cart with Storage Platform, Aluminum Tattoo Tray with Wheels Trolley Adjustable Height, Salon Tray Equipment Service Instrument Storage Tray Accessory for Salon & Spa Use, Black

$44.98 (as of December 22, 2024 00:30 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)CLSEVXY Magnifying Handheld Mirror Double Sided, 1X 15X Magnification Hand Mirror, Travel Folding Held Adjustable Rotation Pedestal Makeup Desk Vanity

$9.99 (as of December 22, 2024 00:30 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Saloniture Professional Portable Folding Massage Table with Carrying Case - Black

$139.99 (as of December 22, 2024 00:30 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)wet n wild Hello Kitty Mirror & Pink Bow Keychain Duo, Comfort-Grip Handle, Versatile & Portable Cruelty-Free & Vegan

$11.04 (as of December 22, 2024 00:30 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Craft beer has a much richer flavor than industrial beer because of the malt. Craft beer malts may contain wheat, but usually not barley as the malt constituent. This is what gives craft beer that wonderful aroma of oven-warmed bread and even cookies.

Craft brewers create new beer recipes using ingredients like mountain spring water, specially ground and toasted malts, and even hops from organic hop producers! Meanwhile, industrial brewers simply don’t have time to tinker like this, whose goal is to produce thousands of liters of beer to maximize income while keeping product prices down. .

2.1 Position of fermentation process when producing craft beer and industrial beer

Yeast can float to the top of the beer mixture during fermentation. The majority of top fermentation occurs during craft beer production.

Industrial beer yeast is fermented from top to bottom, with the main fermentation completed at the bottom. Meaning there’s no need to control it all the time, which is perfect for large-scale brewing. Because industrial beer after fermentation is clarified, and not completely fermented, the production speed is much faster.

2.2 Temperature during fermentation of craft beer and industrial beer

The temperature during craft beer fermentation is from 16°C to 26°C or 60°F to 78°F. Because craft beer fermenters are typically small, the brewer can monitor this stage of production for high quality control and meticulous observation.

Industrial beer fermentation is set between 9°C and 14°C or 48°F and 57°F. Because industrial beer fermenters are very large, temperature settings like this are intended to speed up the fermentation process. The relatively cold fermentation setups used for industrial beer production inhibit the production of esters. This makes the beer cleaner and smoother.

2.3 Yeast used in craft beer and industrial beer

There are literally hundreds of different types of yeast. There are top fermenting yeasts, such as those used in craft beer, and bottom fermenting yeasts such as those used in industrial beer. Temperature, time and sugar react with each other, and all affect the taste of the final product.

2.4 Raw materials for beer production

Craft beer is carefully made using exclusive ingredients, most often locally sourced. These raw ingredients are selected using a rigorous selection process before being allowed to become part of the brewer’s recipe.

2.5 Craft and industrial beer production area

Industrial brewers need large spaces to house their fully automated plants. Hundreds of thousands of barrels of beer must be produced, packaged and distributed every day. For all those consumers living abroad, industrial brewers want their beer to be accessible to customers as well.

Craft beer is usually produced in a small brewery. These are small, compact breweries, often characterized by some functions performed manually or semi-automatically. The “human factor” is an essential ingredient in craft beer production.

2.6 Fermentation of craft beer and industrial beer

One of the important stages in making beer, both craft beer and industrial beer have a fermentation stage, called first fermentation. When the beer mixture uses up all the CO2 gas, this stage is considered complete for industrial beer. However, craft beers have a second fermentation.

During the quieter secondary fermentation, yeast begins working to create more complex flavor and aroma compounds. The solids settle out of the beer mixture and the flavor mellows. This is when the beer’s raw flavors transform into strong, grainy, balanced flavors.

3. Characteristics of craft beer

– Annual output is not much.

– Less than 25% of the brewery’s shares, which can be controlled by non-craft breweries.

– Beer itself is at least one of the brewery’s main products, or accounts for more than 50% of sales.

– Do not use additional substances in the process of creating the product.

– No additives or artificial flavors.

4. The downside of industrial beer

Due to the large scale of production, industrial beers are subject to different quality controls. Premium materials and timing can affect the cost-effectiveness of mass production. Therefore, only the cheapest ingredients are used such as:

– Isinglass: speeds up natural sedimentation, but is actually an extract from the bladder of fish.

– Sugar: corn starch or glucose.

– Propylene glycol: antifreeze used as a preservative.

– Sulphite: occurs naturally in beer but can be added as a preservative.

– Rice: cheap starch

– Vitamin C: used to reduce O2 gas

– Fragrances

Many of the ingredients listed above are what cause the “hangover” feeling in beer drinkers the next day.

5. Conclusion

The distinction between craft and industrial beer production means nothing to those who have found a beer they love and are happy to buy for their own use. Many individuals are turning to brewing their own beer in an effort to reduce costs and have greater control over quality. This is also a good idea that beer fans have always been waiting to discover.